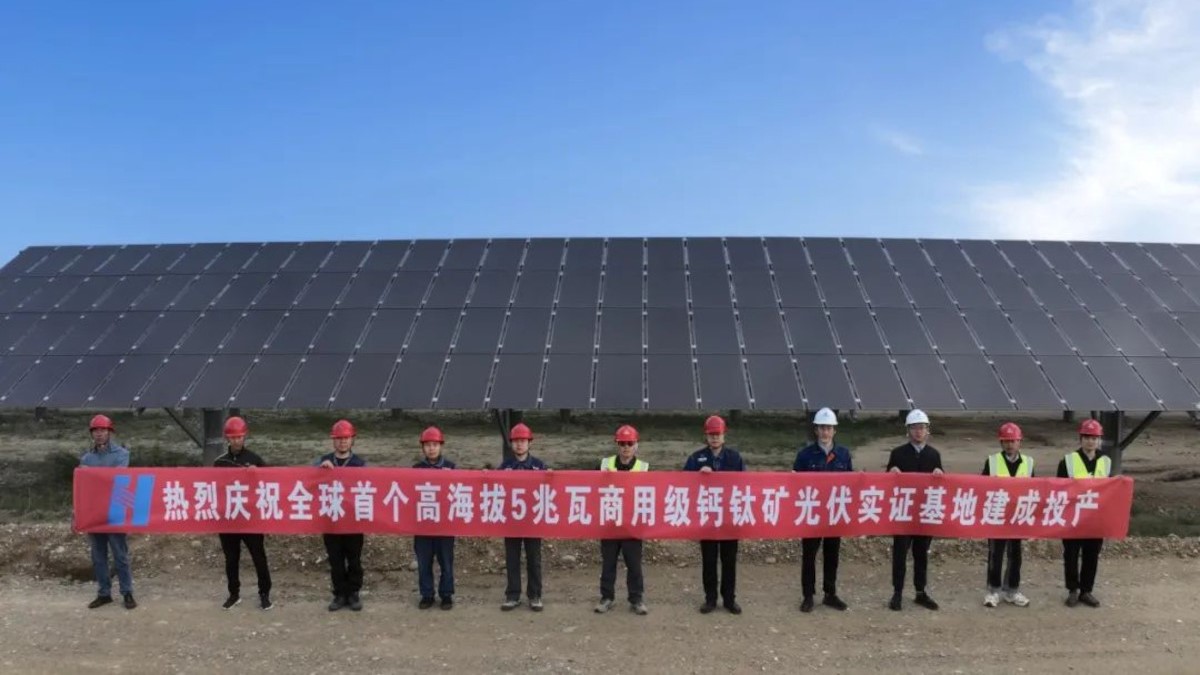

China Huaneng’s Clean Energy Technology Research Institute and China Huaneng Group’s Qinghai unit have commissioned what they describe as the world’s first commercial-scale 5 MW perovskite PV demonstration and verification plant at the Gonghe photovoltaic park in Qinghai province.

The facility, formally brought online on Aug. 23, 2025, aims to generate empirical data on power performance, long-term reliability, and environmental adaptability of perovskite and tandem perovskite/silicon modules under extreme plateau conditions.

The system integrates large-area perovskite modules from domestic manufacturers, targeting more than 90% domestic content for core equipment. Test protocols follow the TÜV SÜD-enhanced IEC 61215 sequence (DH2000/TC400) adopted by UtmoLight Technology: 2,000 hours of damp-heat exposure, 400 thermal cycles, and post-test power degradation below 5%. The program will simulate five years’ cumulative high-altitude ultraviolet irradiation (104 kWh/m²) and assess combined light-and-heat aging at 1.2× standard irradiance (1,200 W/m²) and 60 C.

Huaneng’s laboratory-scale perovskite/silicon tandem cells will also join the program. According to Huaneng, the modules have exceeded 33% conversion efficiency, with laser scribing edge-loss below 0.1 mm and encapsulants with water-vapor transmission rates under 10⁻⁶ g/m²/day, supported by pilot production and demonstration lines bridging lab and commercial workstreams. Key participants include GCL Optoelectronic Material, Microquanta, UtmoLight Technology and Renshine Solar. The Institute of Physics, Chinese Academy of Sciences, is contributing materials-science support, particularly in precursor purity and defect-density control.

Huaneng estimates current perovskite module mass-production costs at CNY 0.8 ($0.11)/W and a highland levelized cost of electricity near CNY 0.15/kWh. It aims to lift module efficiencies above 22% and reduce mass-production costs below CNY 0.6/W by 2026 to approach parity with crystalline silicon.

The company frames the site as both a technical milestone and a standards platform. It is leading efforts to develop perovskite module environmental-adaptation test standards, proposing the inclusion of UV, sand abrasion, and high-altitude pressure factors, and is trialing a “demonstration base plus data-service” model offering monitored module performance for a subscription fee. Project backers say the site will accelerate domestic supply-chain localization and inform applications spanning building-integrated photovoltaics (BIPV), floating, and mobile photovoltaics.

While the demonstration marks a step toward commercialization, Huaneng said long-term data and further scale-up will be necessary to validate durability and cost trajectories before perovskite modules can be widely deployed beyond demonstration projects.